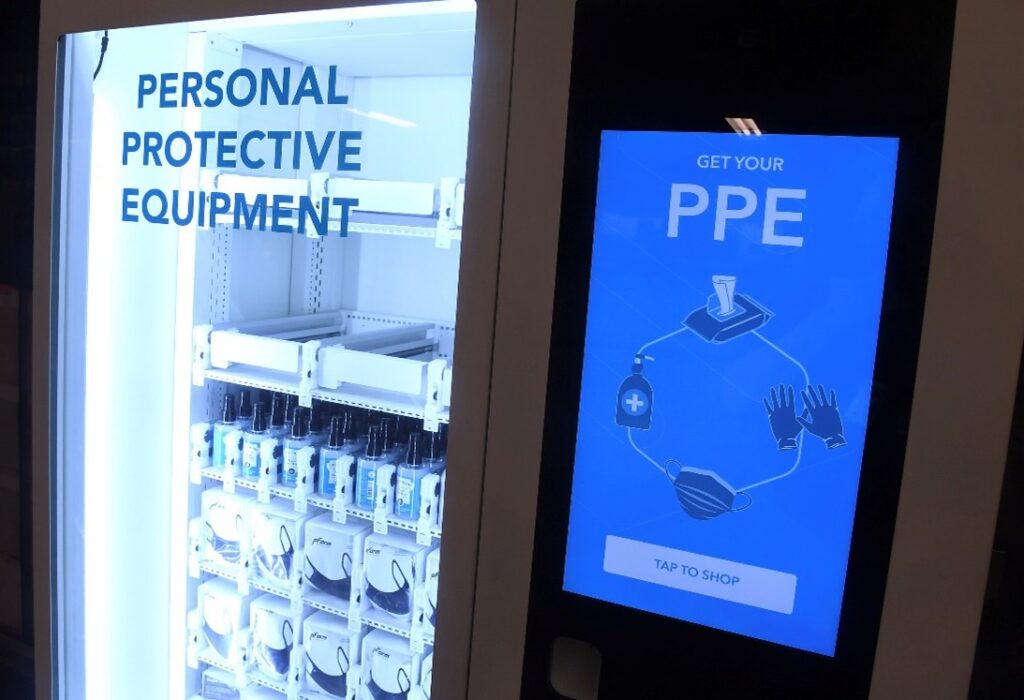

Personal Protective Equipment became a critical issue for people across the globe during the COVID-19 Pandemic. Photo: Marc Herman / MTA NYC Transit.

By Mariana Meneses

During the COVID-19 pandemic, the demand for Personal Protective Equipment (PPE) surged, particularly for general-use masks.

Masks are just one example of PPE, and we take a look at a range of equipment and the latest technological developments that are reshaping the way we safeguard ourselves against injury. From smart wearables to eco-friendly materials, these innovations are revolutionizing the very nature of protection.

Self-decontaminating fabric

Rice University scientists, led by Marquise D. Bell, have made a new kind of material that’s especially good at killing coronaviruses like SARS-CoV-2. The materials does the job in less than 5 seconds, and it can wipe out 99.9% of the viruses. This material can be used to make wearable things like medical gloves, which can be re-used many times. One pair of these gloves can help reduce a significant amount of waste from single-use nitrile gloves.

Graphic showing rapid decontamination by heating. Credit: Marquise D. Bell et al. (2023).

During the pandemic, issues arose with excessive waste from personal protective equipment, and insufficient PPE for healthcare workers and others who most needed to protect themselves and those they served.

The need for PPE that we can use again and again became clear, and researchers began to engineer solutions.

The special property of the new material is that it uses electricity to generate significant heat on the exterior (over 100 degrees Celsius or 212 degrees Fahrenheit), but it stays close to room temperature on the interior where it touches the skin, only reaching about 36 C (97 F). This makes it hot enough to kill the viruses but not so hot that it harms the person wearing it.

Compared to other ways of eliminating viruses, like using dry heat which requires removal of moisture, this method is efficient and reliable and, since it doesn’t damage the protective equipment, is a step forward in safer and sustainable PPE.

Smart Personal Protective Equipment

Smart PPE include protective gear like helmets, ear muffs, and face masks that can connect to the internet and mobile devices. These smart safety tools do more than just keep us safe from dangers: they also collect information, send alerts, and adjust to different conditions.

The elasto-magnetic metamaterial has potential use in protective gear such as helmets. These materials could help dissipate the energy from sudden impacts, reducing the force of the impact and potentially improving the safety of the wearer. Photo: Wikipedia .

For example, they help users to communicate in noisy or hard-to-see places. Some can even adjust the temperature to maintain comfort. Others, like special locks and emergency devices, help prevent accidents with machinery. There are also safety vests that light up for better visibility, and some PPE have sensors that monitor for dangers like gas, chemicals, heat, noise, and more, letting supervisors know if workers are in trouble. Most of these smart PPE items connect to other devices using Bluetooth, allowing them to provide real-time warnings and gather data.

The COVID-19 pandemic has brought significant attention to workplace safety, leading to a growing interest in smart PPE and a market that is expected to grow substantially. Companies like Kenzen focus on physiological monitoring to prevent injuries and detect fevers. Despite challenges, including concerns about privacy and device malfunctions, the adoption of smart PPE is likely to continue growing as companies prioritize worker safety in the post-pandemic world.

According to Perillon, which provides Environmental, Health, and Safety (EHS) management software, the market for this technology will nearly triple, from $3.13 billion in 2021 to $9.05 billion in 2028. While healthcare and medical fields used 23% of smart PPE in 2020, it’s expected that the industrial sector will be the main driver of future growth.

Supper Rubber Band

Scientists at the University of Massachusetts Amherst have developed a new substance, called a metamaterial, that can absorb and release enormous amounts of energy.

Combining an elastic, rubber-like material with embedded tiny magnets, the metamerial been designed to take advantage of a physical property known as phase shift, which greatly amplifies the amount of energy that it can release or absorb. By controlling the phase transitions, the researchers have engineered a programmable substance with predictable and repeatable responses.

Phase shift: “Imagine you are watching waves in the ocean. Each wave has a peak (the highest point) and a trough (the lowest point). Now, let’s say you have two waves, one that starts at the peak and one that starts at the trough. These waves are “in phase” because they start at the same point in the pattern and repeat at the same time. But what happens if you shift one of the waves slightly so that it starts a little bit later or earlier in the pattern? This is called a ‘phase shift’. When you shift the wave like this, the peaks and troughs will no longer line up in the same way. This can cause the waves to interfere with each other, either amplifying or canceling each other out. By understanding how waves can be shifted in phase, we can design devices and systems that use waves to do useful things, like transmitting information or creating images.” – Chat GPT, when asked to explain this complex concept in simple words.

The development of this material is significant because it offers a solution to a longstanding challenge in materials science.

Traditionally, to amplify energy release or absorption, researchers have had to engineer a new material structure at the molecular or even atomic level where the material’s properties are determined. This requires a high degree of precision and control, since the manipulation of these structures requires a deep understanding of the underlying physical principles involved.

Scientists were inspired by the snapping-shut responses seen in nature, such as in Venus flytraps (Dionaea muscipula), a carnivorous plant. Photo: AleksanderSandi.

However, this level of control is difficult to achieve in a predictable way, especially in complex systems, sometimes leading to materials that don’t perform as expected. The development of metamaterials has opened up new possibilities for researchers to engineer materials without the challenges of atomic and molecular control. Metamaterials are materials engineered to have properties not found in naturally occurring materials, which allows researchers to manipulate and control their properties in ways that are not otherwise possible.

The new material was reported in a 2022 paper in the Proceedings of the National Academy of Sciences, led by Dr. Xudong Liang.

The researchers combined an elastic, rubber-like substance with embedded magnets, forming an “elasto-magnetic” material. Doing so allowed them to control the phase transitions of the metamaterial. Because the phase shift is predictable and repeatable, the researchers were able to engineer the metamaterial to do exactly what they wanted it to do.

“Elasto-magnetic metamaterials composed of polymeric networks and interacting magnetic domains.” Image: Liang, X., Fu, H., & Crosby, A. J. (2022).

“A polymer is a substance or material consisting of very large molecules called macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins that are fundamental to biological structure and function.” (Wikipedia)

The rubber-like material they created can store and release energy very quickly, like a spring.

This means that it could be used to make things move extremely quickly or to help protect against sudden impacts by absorbing the energy and reducing the force. It could have a wide array of applications in a wide array, from robotics to protective gear, and in scenarios where high-force impacts or lightning-quick responses are needed.

“[We] have not only made new materials, but also developed the design algorithms that allow these materials to be programmed with specific responses, making them predictable,” said Dr. Alfred Crosby, leader of the Crosby Research Group at the University of Massachusetts, who co-authored the study.

The development of this new elasto-magnetic metamaterial is a testament to the combined creativity of science and engineering, and its potential is significant, setting the stage for metamaterials with wide-ranging compositions, interacting fields, and engineered properties.

By looking to nature for inspiration and utilizing cutting-edge materials science, researchers have created a programmable substance with unprecedented energy absorption and release capabilities. The potential for such materials may well go beyond personal safety, and some are beginning to imagine other ways the technology could transform the world.

Innovations, like self-decontaminating fabric that can swiftly neutralize viruses, are addressing pressing issues of PPE waste and sustainability. The rise of internet-enabled PPE that gathers and transmits real-time safety data has gained significant momentum with the promise of improved safety in various industries. The value of the global PPE market, which was $71.05 billion in 2021, is expected to increase to $110.85 billion by 2029, growing at a rate of 4.7% each year.

As the PPE market continues to grow, driven by heightened awareness of safety needs, it’s clear that these developments are reshaping how we protect ourselves in a rapidly changing world.

Additionally, breakthroughs in materials science, exemplified by elasto-magnetic metamaterials, offer exciting prospects for energy absorption and impact protection in various applications. The future holds the promise of safe, efficient, and sustainable PPE technologies, as science and engineering push the boundaries of what’s possible in the realm of personal protection.

Interested in exploring related topics? Discover these recommended TQR articles.

- Clean Technologies and Technologies That Clean: Undoing the Climate Damage We Have Caused

- Harnessing Ocean Power: New Technologies Hold Promise for Clean and Cost-Effective Energy

- Revolutionizing Food Production to Power a Growing World Population

- Life Beyond Plastic: How Insects and Enzymes Could Hold the Key to Solving Plastic Pollution

- Aquaculture Technologies Hold Promise for an Efficient, Sustainable Global Food Supply